Sanding heads are a huge help in our work, but since there are so many different types, it's easy to get lost among them, which one is for what, how to use and clean them - let's take them one by one.

Carbide, diamond dust, stone cutters

It is very important to distinguish sanding heads according to their material, because it largely determines what they can and should be used for. Thanks to their special material, the carbide heads heat up less than previous paper sanding rings, and their service life is also much longer, they can be used well for months or even years. The surface of the carbide heads is milled, which means that the material is grooved, without any additional coating. These heads are basically used to remove and thin artificial nails and gel polish material, and the smaller version is used to lift stuck cornices.

A thin layer of coating is found on the surface of the diamond powder cutters, which results in a rough surface suitable for a fine file. These heads are usually used to remove stuck-on skin, clean corns, and thin dry calluses.

The stone heads are mostly used during pedicures to refine the skin and to remove the skin stuck to the nail, in fact, they can be considered another version of the diamond dust cutters. Due to their softer, less resistant material, these heads should be used carefully and only very delicately on the nail plate, otherwise they lose their strength prematurely and may wear out.

Which form should I choose?

In addition to the material of the sanding heads, it is the shape that determines the function. The wide cylinder-shaped heads are mainly used for thinning and removing the material of artificial nails and varnish gel, e.g. Grinding head - for silver, porcelain). Rollers with a rounded head allow safe work next to the skin (for example , Galaxy Sanding Head - Carbide Rounded Roller - For Material Removal ). The narrower heads in the form of a cylinder easily fit into the ramparts near the edge of the nail, so we can use these heads either for filing out air during filling or for filing together at the end of the work process.

The cone-shaped heads are excellent for filing the surface, for thinning the parts next to the skin and even for filing from the free wind side, whether it is for corrective thinning, the lower step or for filing the natural nail plate (e.g. Grinding head-Carbide pointed cone).

The larger versions of the ball heads can be used for material removal and thinning, as their wide belly effectively grinds the material from most of the nail, and with its thinner tip you can easily reach the parts next to the skin (e.g. Grinding head - Big lamellar ball). With its smaller version, the stuck-on skin can be easily lifted, making it easier to cut the cuticle (e.g. Grinding head - Carbide ball small).

Mace shapes are mostly used to lift the cuticle and clean the cuticle, as their thin tip reaches the deeper parts of the cuticle, removes stuck-on dry skin, and its wider body creates a distance between the nail plate and the cuticle, thus facilitating material application (for example, Galaxy sanding head - Mace with diamond dust - For manicure).

Cleaning

Physical cleaning is a very important first step, with which we remove dust, skin, and material residue stuck to the sanding head. In the case of carbide and all milled heads, we feel free to use the metal Grinding Head Cleaning Brush , which, thanks to its strong fibers, removes deposits even from the depths of the grooves. However, in the case of diamond and stone heads, be careful, because the metal brush can remove the diamond dust coating, these cutters should be cleaned with a nail brush with stronger bristles.

As a second step, apply a disinfectant, which means spraying in the case of the spray version, soaking in the case of normal liquid, or possibly ultrasonic cleaning. It is important to always apply the correct exposure time and to check whether the disinfectant should be washed or wiped off the metal tools, so as not to damage them.

Article author:

Piece Year

Share:

Favorite colors of the tropics

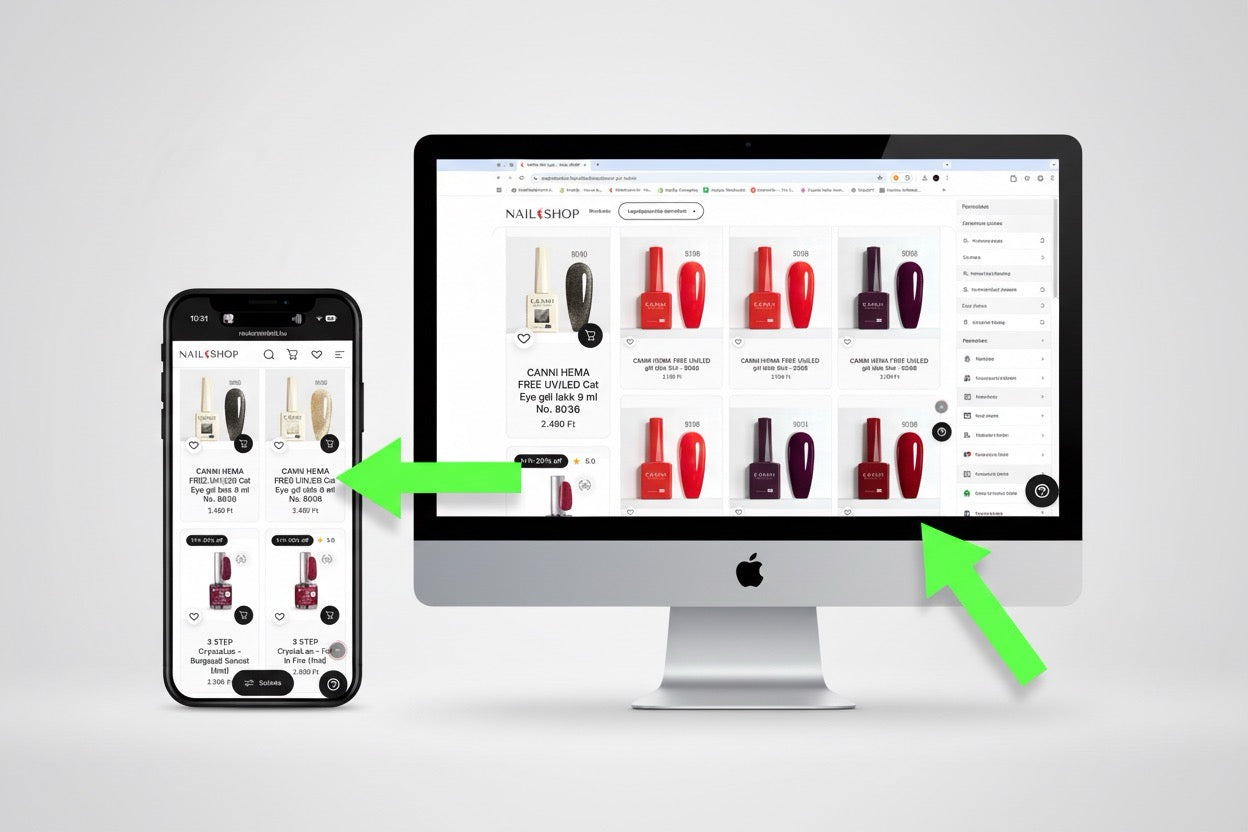

Which nail bed colors are suitable for which skin type during construction?